Projects Agile

Not every solution starts in a product catalog. Projects Agile is a specialty service offered by Tecoustics that focuses on complete customization of Engineering and Product Integration tailored to the exact specification requirements of the project.

Projects Agile provides customized disruptive technology and solutions for complex projects and rapid construction schemes. Incorporating our most senior staff in our Mechanical and Structural Engineering and Analysis Groups, as well as leveraging the most technology possible in design, rapid prototyping, physical testing, and automated manufacture and fabrication, Projects Agile provides the fastest, most expansive and agile “solutioneering” in the industry.

Projects Agile collaborates, and integrates solutions for Mechanical, Plumbing, Sheet Metal, Noise Control, Vibration Control, Thermal Control, Structural, Fabrication and Logistics streams. Our partnership network of industry leaders and our robust supply chain can bring full-scope solutions integrating all major disciplines to bring solutions to all levels of construction obstacles. The engineering, design and manufacture within the Projects Agile group is built on a solid foundation of Lean Construction methodologies.

Customization

Project and Equipment specific custom designed and manufactured products incorporating the required performance specifications and site-specific constraints.

Tecoustics can custom design Compression and Extension Springs and the accompanying housing for any application and performance specification. Hot-Coiled and Cold Wound, Diameters and Free-Lengths and Commercial or Precision grade for any application. Tecoustics will work with the client to design the spring properties for the specific application, lifespan and environment of operation.

Custom molded rubber mounts, pads and bearings to suit project and site-specific requirements for any load and deflection. Tecoustics can custom tailor the elastomer to offer exotic properties such as low-static, temperature stability, extreme tensile performance, AASHTO quality and embedded plates and inserts.

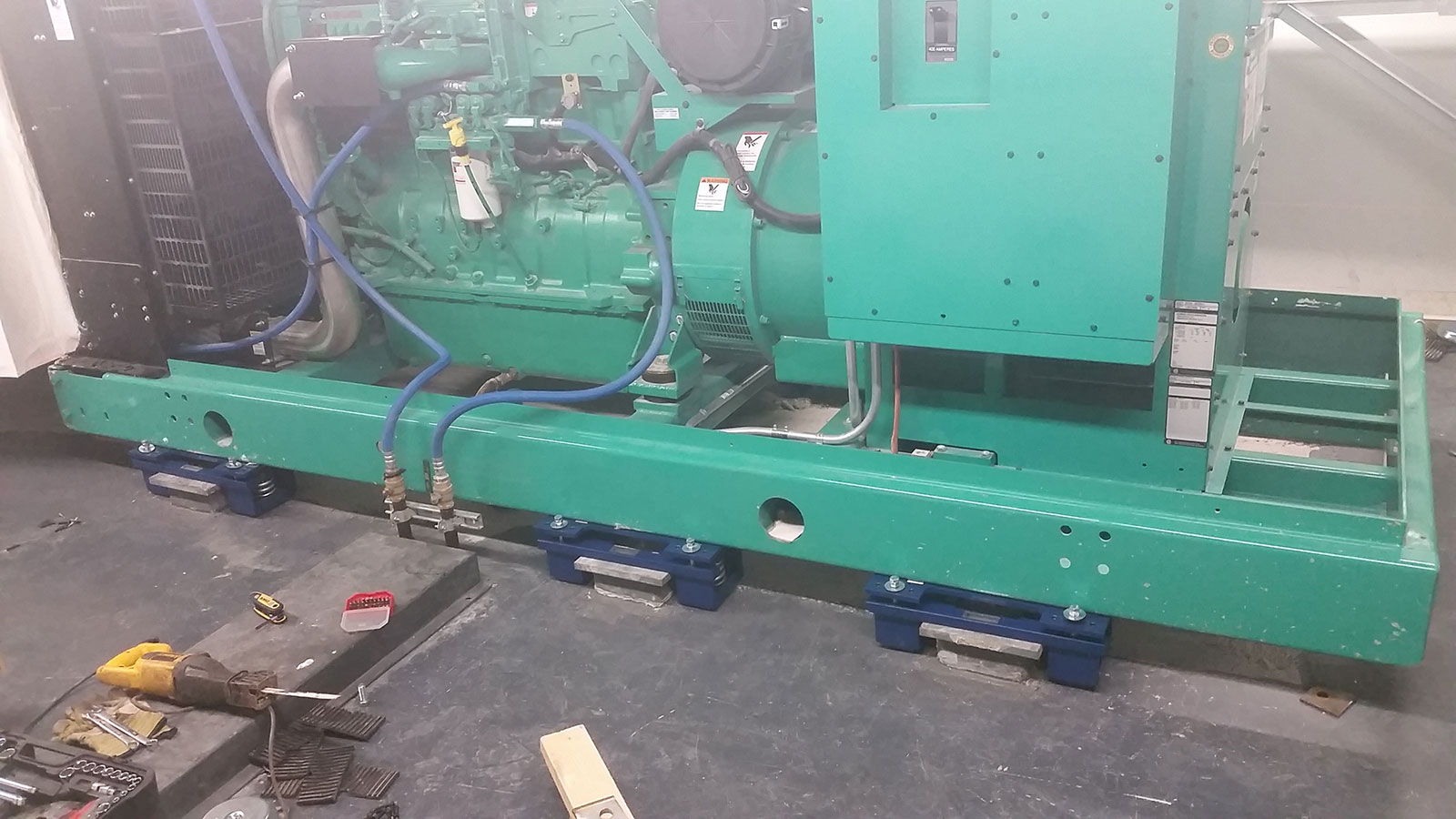

Mitigation

Vibration and Architectural Acoustics Mitigation solutions for problematic Equipment or Systems within a building. Tecoustics can custom design and manufacture a solution to meet Performance, Adjustability, Installation and Site-Specific Constraints to bring compliance to your project. Services range from Design and Supply to Turn-Key which includes installation and potential removal of existing controls.

- Vibrating Equipment - Limit transfer of vibration from equipment to building

- Sensitive Equipment - Limit transfer of vibration from building to equipment

- Room to Room - Limit transfer of Vibration and Acoustics between Rooms and Floors

- Exterior - Limit transfer of vibration and noise from the environment and exterior sources to the buildings interior

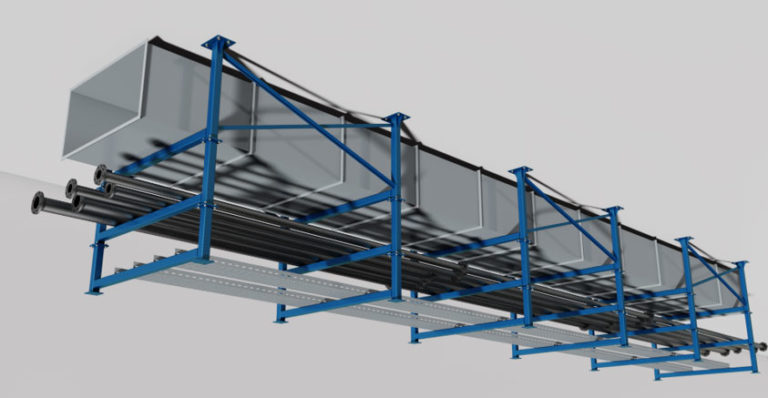

Design for Manufacture and Assembly (DfMA)

Design for Manufacture and Assembly (DfMA) to provide modular solutions for rapid construction schemes.

DfMA is one of the fundamentals to execute lean and agile methodologies to transform traditional construction which assists in eliminating process waste and enhances quality through the integration of systems and components to maximize offsite manufacture. This methodology will optimize site labour, speed site assembly processes and improve quality versus traditional construction processes.

The goal of our DfMA strategy is to integrate all specialty components and engineering systems into modules to provide customers with additional assurance to protect installation performance and quality targets. DfMA also contributes to improved health and safety performance as field operatives perform simpler assembly tasks for a shorter period of time, and with less physical effort over traditional construction methodologies.

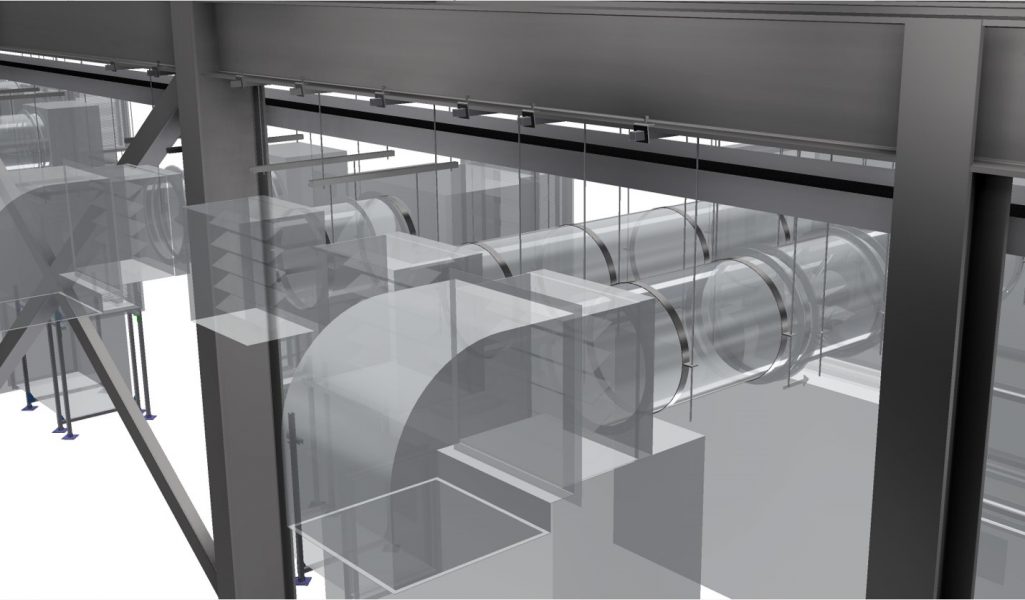

Plant Integration and BIM Lay-In

Integration of specialty components and designs into your Mechanical Room, Central Utilities Plant, Boiler Room, or Industrial Facility. Feasibility and transport coordinated models. Detailing and clash analysis for new and existing systems and structural components. Tecoustics can generate 3D models for integration into new or existing BIM, and integrate all engineering and specialty applications into the model. Site scanning using Laser or Photogrammetry scanners can be utilized to develop a point cloud for generation of an integrated 3D model.